Do you know non woven bonding techniques? In this article, we will discuss the thermal bonding nonwoven process, its advantages, and its applications. Let’s start with thermal bonding definition.

What is thermal bonding?

Thermal bonding, also known as ‘heat bonding’ or melt bonding, is a process that actually melts the web together at fibre crossover points.

In this process, the web is passed through a source of heat, such as pressurized steam or hot air, which causes fusion at fibre crossover points.

Thermal Bonding Nonwoven Process

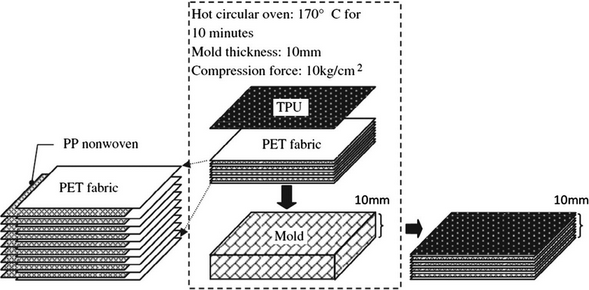

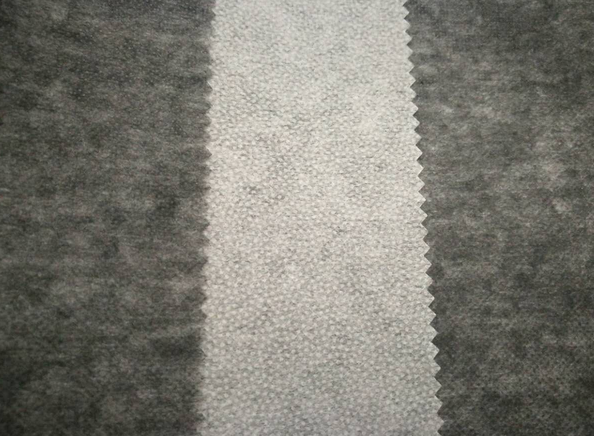

The thermal bonding nonwoven process involves the use of heat and pressure to melt and bond synthetic fibers together. The process begins with a blend of synthetic fibers, typically polypropylene or polyester, which are carded into a web. The web is then passed through a heating chamber where it is subjected to high temperatures, causing the fibers to melt and bond together. The heated web is then pressed between two rollers, which apply pressure to the fibers, further bonding them together.

One of the primary advantages of the thermal bonding nonwoven process is that it does not require any adhesives, making it a cost-effective and environmentally friendly option. The process also allows for greater control over the porosity and thickness of the resulting fabric, making it suitable for a wide range of applications. Additionally, the resulting fabric is strong, durable, and resistant to tearing, making it ideal for use in harsh environments.

The thermal bonding nonwoven process is commonly used in the production of disposable medical and hygiene products, such as surgical gowns, face masks, and baby diapers. These products require a nonwoven fabric that is soft, breathable, and comfortable to wear, while also providing protection against bacteria and other pathogens. The thermal bonding process allows for the creation of a fabric that meets these requirements, while also being cost-effective and easy to manufacture.

Another application of the thermal bonding nonwoven process is in the automotive industry. Nonwoven fabrics produced using this process are commonly used in the production of automotive interiors, including headliners, door panels, and trunk liners. These fabrics provide excellent insulation and sound absorption properties, while also being lightweight and easy to shape.

Finally, the thermal bonding nonwoven process is also used in the production of filtration materials. Nonwoven fabrics produced using this process can be used as air filters, oil filters, and water filters, providing excellent filtration efficiency and durability.

Thermal Bonding is the most popular method of bonding used in nonwoven manufacturing. Our Polyester thermal bonding nonwoven fabrics are been used in households like honeycomb curtains, MERV, HEPA, in garments like interlinings, in electronics like desiccant, in medicals like PPE, face masks. If you are looking for non woven material manufacturers, Pls contact us.